In our range you will also find the complete range of inks and additives that you need when coding and marking:

- General purpose black inks: The Linx range of general purpose black inks is characterized by outstanding performance on most common materials, ideal for most general external applications on packaging.

- Special inks for better adhesion: Designed for applications where manufacturing processes can challenge the adhesion or durability of other inks. Coding inks on plastics and plastic films such as nylon, polyethylene, polypropylene (including untreated OPP and BOPP) and polyvinyl chloride.

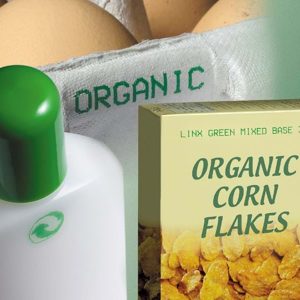

- Food Grade inks for the food industry: Contains only edible raw materials in accordance with United States Food and Drug Administration (FDA) or European Union (EU) regulations.

- Contrasting colors: A palette of pigmented inks that deliver vivid codes in a variety of colors on a range of materials including rubber, plastics and metals. They also offer good heat tolerance, light fastness and solvent resistance.

- Inks for specific processing: Designed for more demanding applications where the substrate is subjected to additional processes, e.g. steam sterilization or dry washing.

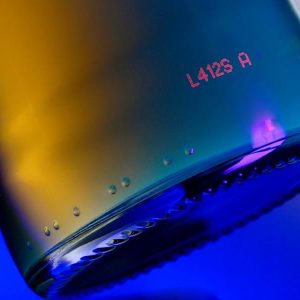

- Safety (UV readable) inks: Inks that are almost invisible near normal light, but glow purple or red under UV light. Suitable for use against counterfeiting as well as for other discrete applications.

- Color inks for pale substrates: provide strong contrast when used on a variety of colored substrates. For better readability of the code or it can be used to fit into the branding of discrete coding packaging.

- Special inks for marking large characters: they dry quickly and have a weak smell, which makes them especially suitable for food packaging. Applications may include transport packaging coding, product identification, corporate branding, contact information, or ingredient lists.