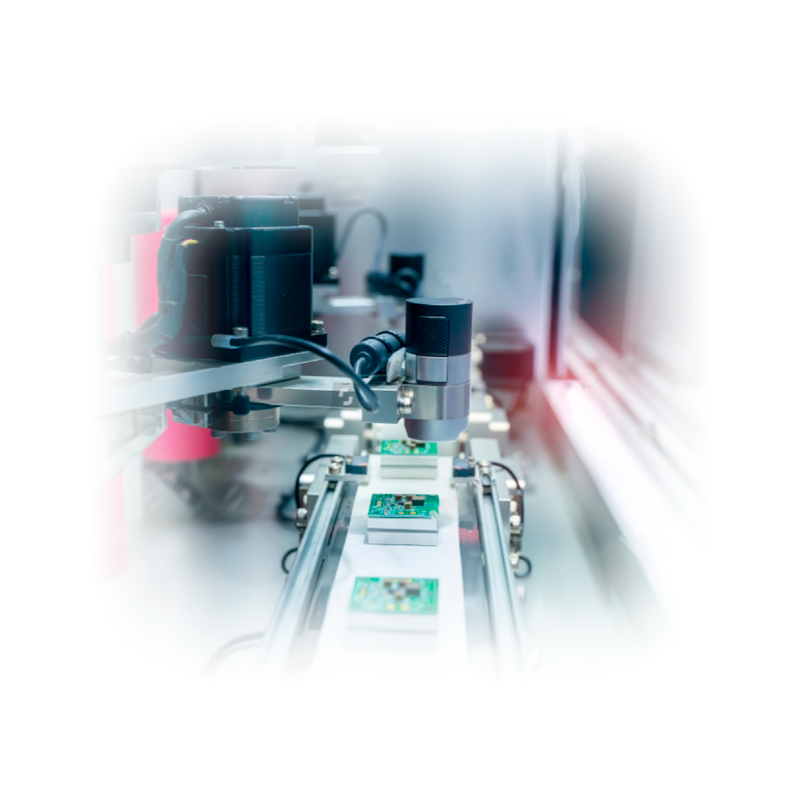

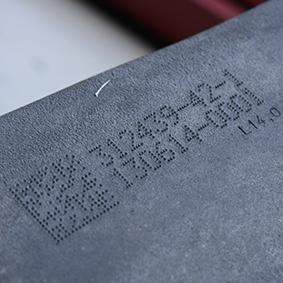

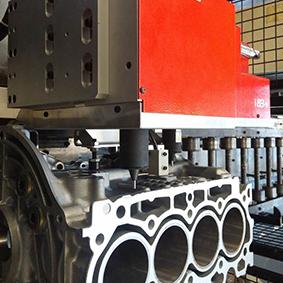

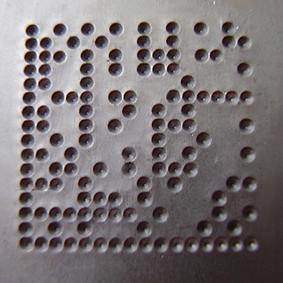

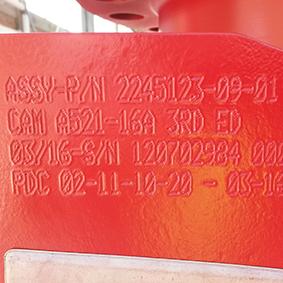

The E10 R i53 dot peen marking head was engineered for seamless integration into automatic production lines. Its compact, lightweight design requires minimal maintenance and consumables, and no separate pneumatic system. Easy to use, this integrated marking system can mark components of various shapes and surface materials, and will mark any material including plastics and hardened steel (up to 62HRC). Its electromagnetic driving technology allows permanent marking on parts of various shapes and surface finishes, whether flat, concave, convex, circular, raw, or machined.

The machine’s internal components are protected by a heavy duty steel case, while flexible bellows allow continuous industrial use. The quality and accuracy of the guidance, the wide tolerance between the stylus and the part, and the speed and power of the integrated software make the i53 a high-performance tool that is super easy to operate, even with minimal training.

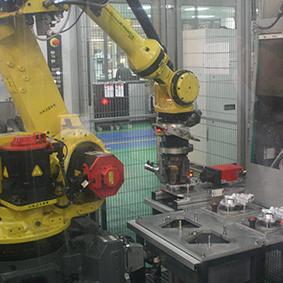

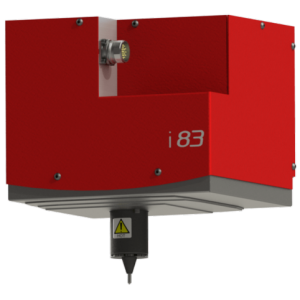

E10 R I83 is specially engineered to integrate into automated production lines. Easy to operate, automatically detects the marking surface, which allows fast marking on components of different shapes, sizes and surface materials.

In addition to marking plastic and hardened steel (up to 62HRC), its unique electromagnetic technology does not require a special pneumatic system. I83 requires minimal maintenance, without consumables. Its internal components are protected by a thick steel frame that allows intensive industrial work, even in the harshest environments.

The cable is easily removed for quick and easy replacement when needed. Easy to use, with minimal training. Effortless work is enhanced by quality and accuracy and wide tolerance between the needle and the products, making the I83 an impeccably reliable marking machine.

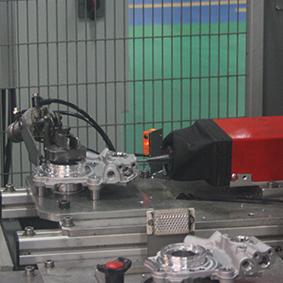

E10 R I113D marking head is easily integrated into automated lines in industrial environments. Its simple use makes it possible to mark parts of different shapes, surfaces and materials. Quickly produces a mark (up to 0.8 mm on standard steel) using dot peen technology on all types of materials. The speed and power of integrated software make it a high-performance system.

The integrated marking system i141 is a compact dot peen marking head specifically designed for seamless integration into automated production lines, and can be mounted in any position (up, down, side-ways). Its large marking window and electromagnetic driving technology allow for permanent, deep marking on various surface shapes and materials (flat, concave, convex, circular, raw, machined, etc.). The integrated marking solution i141 can mark any material, from plastics to hardened steel (up to 62HRC). The internal components are protected by a steel case, while flexible bellows allow continuous industrious use.