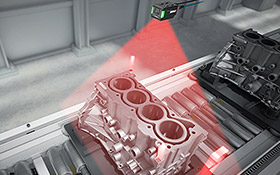

1D / 2D code reader

Extremely wide field of view that is 4x wider than conventional models. It allows easy reading of multiple codes and different code positions.

With more than twice the reading distance compared to conventional models, there is no need to control the position of the code or change the tool.

Read codes on the move, from conveyor belts to robotic applications.

Examples of applications:

Reading codes at different places on engine parts

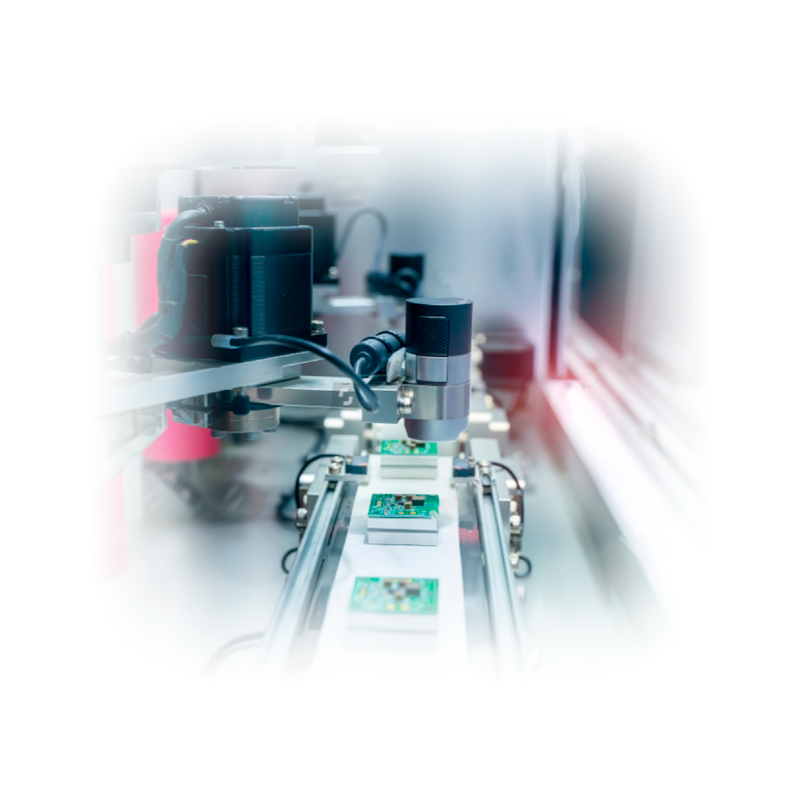

Reading codes on multiple electronic PCBs at once

Read codes on different tire sizes

Improving the productivity of semi-automatic equipment

Read codes at different heights using only one reader

Faster operation without stopping due to the code reading process

Read codes on boxes of different heights

Autofocus 1D and 2D

The code reader automatically optimizes the settings, adjusts the position of the code, and the operating conditions can be easily verified by the intuitive embedded display.

Installation is less limited by the performance or specifications of the code reader itself, which improves flexibility in the design of the machine for production lines. With the help of the autofocus option, one reader can register codes on objects of different heights.

The code reader automatically eliminates the reflection, so there is no need to adjust the angle or external lighting during the installation. When combined with the autofocus function, the mounting becomes very flexible.

Ultra compact 1D and 2D code readers

This series offer high performance and fast code reading in a compact body that ensures easy integration into existing systems. Tracks are simple, so new users will easily understand.

The compact housing can be mounted in small spaces, which extends the scope of applications. New algorithms provide the best readability even when the code is difficult to read. Compatibility with different communication protocols.

Compact 1D and 2D high-performance code reader

The readers of this series allow reliable code reading even from surfaces where the codes are poorly visible, such as black resin, metal, printed circuit boards, scratched, uneven and curved surfaces.

A new algorithm for identifying and processing code has been adopted to allow stable reading.

Simple three-step adjustment.

The code reader checks the image quality.