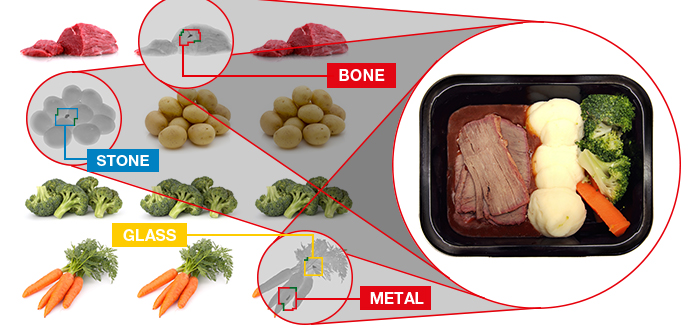

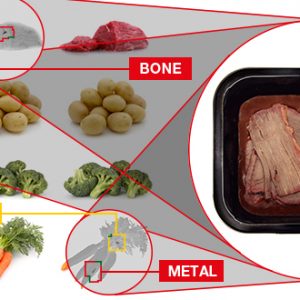

X-ray contamination detection

This type of equipment ensures the safety and correctness of the product in terms of detection of different types of foreign bodies such as glass, metal, plastic, stone, and the detection can also be carried out for products packed in aluminium foils.

These systems are a useful way of monitoring the quantity and weight of a product while the operation of the system has no detrimental effect on the product itself due to the limited time product spends under the x-rays. They can be used at any stage of the production process, which provides a quick and easy way to detect foreign bodies in products and contributes to product safety and security, therefore to the safety of both consumer and manufacturer.

This system can also detect irregularities in products ranging from deformed pieces, cracks, lumps, or cavities. The application of these systems can be done in the food and other industries.

WIPOTEC has developed a comprehensive portfolio of X-ray contamination detection systems that maximize product safety and packaging integrity. Each WIPOTEC X-ray system comes with built-in intelligent software for maximum inspection of your products. X-ray detection system options also include the ability to integrate checkweigher as well as visual inspection.

Contaminant detection for horizontal / flat products:

SC-E 3000/4000 series, SC-WD, SC-2000, SC-3000/4000/5000/6000

- Fast and easy integration due to device compactness and open interface

Intelligent software covering a wide range of applications - Top quality engineering for highest performance – 100% designed and manufactured in Germany

- Numerous software tools allow you to view foreign bodies, check products and complete the packaging

- Compact design

- Diode detector resolution 0.4 mm (0.8 mm on request)

- Maximum inspection speeds up to 1.5 m / s

- 16-bit camera technology

- Intuitive user interface

- Multi-lane detection capability

- Changing toolless conveyors

- Comprehensive software package (optional)

Contamination detection for vertical / tall products:

SC-S and SC-S series with leak detection

- Flexible component design and compact device

- Inspects standing products such as cans, bottles, PVC containers, etc.

- Integrated transportation systems

- Four application features in one machine

- Reliable micro leak detection: 0.1mm or more hole detection

- It is easy to integrate into existing lines

- The modular design allows for compact, curtain-less construction

- It is easy to clean thanks to the hygienic V2A stainless steel design

- Integration of on-demand visual inspection

- Optional: Intelligent analysis of all measured values (incl. Pressure) for process control and comprehensive verification

Contamination detection in bulk / loose products:

SC-B, SC-WD-B Series

- Ideal for detecting feedstock, the contaminant is removed before entering production, thus reducing the percentage of defective final product

- For use in dry bulk products such as rice, coffee, nuts and the like

- IP65 protection

- Easy to integrate into existing lines

- Different ejection systems like compressed air knives

- Diode detector with 0.4 mm resolution

- Available in different widths